G 2T® Cast Lined Pipe Ceramic Lined Wear Pipe

G 2T®

G 2T lined wearpipe is a seamless, monolithic lined pipe designed to provide maximum abrasion resistance in the most challenging environments.

G 2T Lined pipes consist of a layer of engineered alumina ceramic material applied to the inside wear surfaces of the pipe, then spun cast or troweled in place. The result is a monolithic liner with no seams or tiles. After curing the liner retains a hardness of between 8 & 9 on the Moh’s scale, yielding one of the best wear solutions for the most erosive applications.

G 2T cast lined pipe has been engineered to provide exceptional wear resistance in corrosive and high temperature environments. The chemical composition G 2T and seamless application limit the effects of corrosion in many applications. In addition, the high temperature capabilities of G 2T and good thermal shock resistance can provide exceptional abrasion resistance that no other material can match in environments up to 2200° F.

The combination of corrosion resistance and high temperature capabilities provide unquestionable advantages over the most common pipe materials such as; basalt, rubber, polyurethane, steel, cast iron or ceramic tile.

Advantages

- Dramatically extends the life of piping that is subject to severe erosion and corrosion

- Superior abrasion resistance, typically > 8 Moh

- Seamless, monolithic liner – No tiles

- Good resistance to chemicals, including diluted acids, alkalis, and bases

- Out performs Basalt lined pipe in most applications

- Wide size variety of pipe for most applications

- Reduces life cycle maintenance cost, and unplanned outages

- Available in straights, bends, wyes, tees & reducers

- Operates in temperatures up to 2195° F (1200° C)

Sizing For 1/2″ Thick Lined Pipe

(for reference only)

| Sch #10 | Standard | Sch #40 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NPS | O.D. | Wall | ID | lbs/ft | Wall | ID | lbs/ft | Wall | ID | lbs/ft |

| 4 | 4.50 | 0.12 | 3.26 | 13.4 | 0.24 | 3.03 | 18.1 | 0.24 | 3.03 | 18.1 |

| 5 | 5.56 | 0.13 | 4.30 | 17.6 | 0.26 | 4.05 | 24.0 | 0.26 | 4.05 | 24.0 |

| 6 | 6.63 | 0.13 | 5.36 | 21.4 | 0.28 | 5.07 | 30.4 | 0.28 | 5.07 | 30.4 |

| 8 | 8.63 | 0.15 | 7.33 | 29.5 | 0.32 | 6.98 | 44.0 | 0.32 | 6.98 | 44.0 |

| 10 | 10.75 | 0.17 | 9.42 | 39.1 | 0.37 | 9.02 | 60.1 | 0.37 | 9.02 | 60.1 |

| 12 | 12.75 | 0.18 | 11.39 | 48.7 | 0.38 | 11.00 | 73.3 | 0.41 | 10.94 | 77.1 |

| 14 | 14.00 | 0.25 | 12.50 | 63.5 | 0.38 | 12.25 | 80.9 | 0.44 | 12.12 | 89.4 |

| 16 | 16.00 | 0.25 | 14.50 | 72.9 | 0.38 | 14.25 | 93.0 | 0.50 | 14.00 | 112.6 |

| 18 | 18.00 | 0.25 | 16.50 | 82.4 | 0.38 | 16.25 | 105.1 | 0.56 | 15.88 | 138.4 |

| 20 | 20.00 | 0.25 | 18.50 | 91.9 | 0.38 | 18.25 | 117.3 | 0.59 | 17.81 | 160.7 |

| 22 | 22.00 | 0.25 | 20.50 | 101.4 | 0.38 | 20.25 | 129.4 | — | — | — |

| 24 | 24.00 | 0.25 | 22.50 | 110.8 | 0.38 | 22.25 | 141.6 | 0.69 | 21.62 | 217.1 |

Comparison

Based on Mild Steel

| Mild Steel | G 2T Cast Lined Wear Pipe |

|

|---|---|---|

| Hardness | 120-150 BHN | 300-700 BHN |

| Max Temperature | 750° F (400° C) | 2195° F (1200° C) |

| Abrasion Resistant | Poor | Excellent |

| Impact Resistant | Good | Poor |

| Std. Sizes (OD) | Unlimited | 4″ to 24″ |

| Handling/Installation | Excellent | Heavy & Brittle |

| Fabrication | Unlimited | Very Limited (to pattern) |

| Emergency Repair | Easily Patched | No |

| Initial Cost | 1 | 5+ |

| Life Expectancy | 1 | 6+ |

Hardness Profile

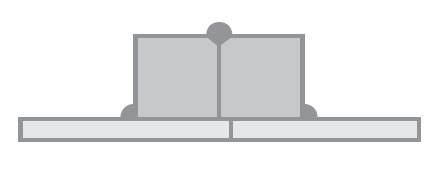

The outside surface is mild steel for easy welding and the interior of the pipe is lined with engineered G 2T ceramic material.

FABRICATION

We recommend the use of St. Lawrence’s fabrication services to eliminate processing and fabrication errors.

End Options/Coupling Methods

We offer a wide range of options including:

Field Fabrication/Modification of Pipe

This section covers the field welding and cutting of our wearpipe products. It is intended solely as a guide. All St. Lawrence’s pipe products must be supported on both sides of the cut area to prevent damage to the pipe and or cutting equipment. Normal safety and workmanlike practices are recommended.

Cutting

WARNING: Ceramic lined pipe must be supported on both sides of the cut area to prevent damage to the pipe and/or cutting equipment.

Ceramic lined pipe can be cut with an abrasive saw using an abrasive silicon carbide wheel. Working in 6 ̋ to 8 ̋ section of the outside diameter, cut the steel layer of the pipe shell only, avoid penetrating into the G 2T liner section of the pipe. After completion of cutting the steel layer, cut the G 2T layer. Repeat this procedure around the OD of the pipe.

Joint Preparation

Inspect surfaces to be welded – avoid welding areas that have tears, cracks and other discontinuities. Clean joint area at least 1/2 ̋ from welding joint; remove all loose scale, rust, moisture, grease, etc. Bring parts into as close contact as practical; root opening should not exceed 3/16 ̋. For separations greater than 1/16 ̋, increase leg of fillet weld by the amount of the opening.

Liner Touch-up

All chipped areas should be filled with G 2T from St. Lawrence. Allow proper curing.

WELDING

1) General Instructions

Working from the exterior of the pipe join the pipes using a low carbon electrode. Allow the pipe to cool before proceeding.

2) Preheating

If ambient temperature of parts is below 70° F, preheat the weld zone and 6 ̋ of the adjacent material to 100° F.

3) Consumables

Any low carbon electrode is acceptable. (AWS 5.1 – E7018 or 7016 type), 1/8 ̋ or smaller should be used.

End Options/Coupling Methods

We offer a wide range of options including:

Standard Weld Rings

- Typically no face seal weld.

- Most common style.

- Butt weld field applied.

Self-Aligning Weld Rings

- Male/Female recess.

- Butt weld field applied.

Victaulic End Styles

- Fast installation

- Low working pressure

Standard Flanges

- 150#, 300# or 600# most common: others available.

- Industry standard dimensions.

- Raised face (shown) & plate flanges.